- Home

- Freezer Room

- CONTROLLED ATMOSPHERE COLD ROOMS

CONTROLLED ATMOSPHERE COLD ROOMS

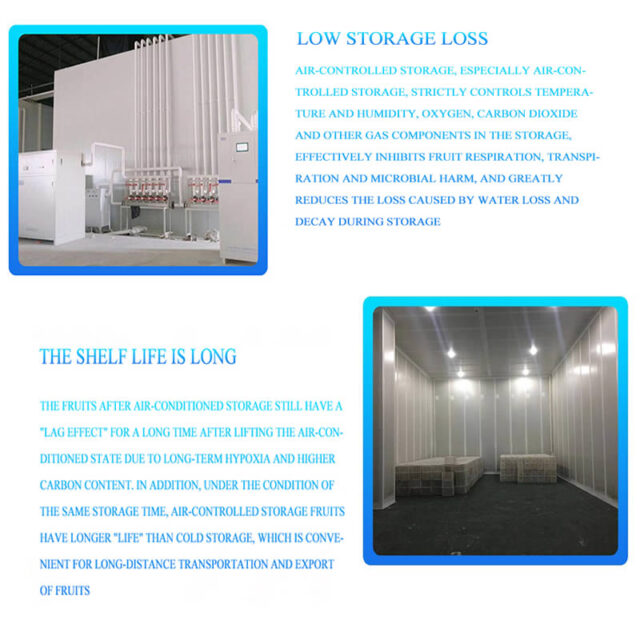

The advantage of installing a Controlled Atmosphere cold room system is to manage the ambient of the warehouse and reduce the oxygen level. The system will also be responsible for increasing the carbon dioxide levels to ensure that your products are fresh and suitable for consumption. This system will be very helpful to preserve vegetables and fruits. The system will reduce the quick ripening of fruits by reducing the level of oxygen that will be dispatched within the warehouse.

- General Details

- Contact Us

- Related Products

The advantage of installing a Controlled Atmosphere cold room system is to manage the ambient of the warehouse and reduce the oxygen level. The system will also be responsible for increasing the carbon dioxide levels to ensure that your products are fresh and suitable for consumption. This system will be very helpful to preserve vegetables and fruits. The system will reduce the quick ripening of fruits by reducing the level of oxygen that will be dispatched within the warehouse.

Another incredible advantage of a Controlled Atmosphere system is the fact that your vegetable and fruits will remain fresh without using any chemicals. Other benefits of a controlled atmosphere cold room are;

● Your agricultural products remain fresh and eatable

● You can store your agricultural products and meat for a long time

● It saves you cost and other overheads

● If you have a well-controlled atmosphere cold room, there may be no need to build different cold rooms for your products

● This is helpful if you are not interested in storing your products for a very long time

● The cost of building a controlled atmosphere cold storage system is far less than building a cold room

● They consume lesser energy compared to other cold storage facilities

We provide services such as;

● The installation of atmosphere control equipment like Nitrogen generators and so on

● Design and build gas-tight rooms and doors

● Controlled cooling systems

● Build and install compressors

● Build and install panels

● We carry out regular maintenance on controlled atmosphere cold storage systems

● Design and fabrication

● Refurbish controlled atmosphere cold rooms

Some of the reasons why most clients hire us to build there controlled atmosphere cold rooms are because we;

● Build all our systems in accordance with the best industry practices

● Our systems consume less energy and perform at the optimal levels

● Produce modern systems that are controlled with knobs and remotes

● Build systems that produce little or no sound

● Our prices are affordable

● We have a team of experts that have vast knowledge about these systems

200mm Cold Room Pu Sandwich Panel

ZKGY cold room pu sandwich panel, 50mm, 75mm, 100mm, 120mm, 150mm,180mm and 200mm thickness, 0.3mm to 1mm color plate, 304 stainless steel. The flame retardant grade is B2. PU panel are injected with 100% polyurethane (CFC free) with an average foam-in-place density of 42-44kg/m³.With our cold room panels, you can efficiently insulate your cold room and freezer room.

50mm/75mm/100mm/150mm EPS Sandwich Panel

50mm/75mm/100mm/150mm EPS Sandwich Panel :EPS sanwich panel is widely used for wall and roof of mobile office/building, gymnasium,villa, guard booth, floor heating , steel structure building and packaging industry,Purification workshop ceiling, warehouses.EPS sandwich panel is a proven construction material well-suited to the extremes. It is a cost-effective, lightweight construction material with excellent insulation properties. ♦ The advantages of EPS Panel include: ♦ High load bearing capacity at low weight ♦ Effective and durable thermal insulation ♦ Absolute water and vapour barrier ♦ Air-tightness for controlled environments ♦ Long life, low maintenance ♦ Lightweight, fast and economic construction ♦ Hygienic food grade finish ♦ Most cost effective insulation material available

Cold Room 50mm Pu Sandwich Panel

CAS GYW cold room pu sandwich panel, 50mm, 75mm, 100mm, 120mm, 150mm,180mm and 200mm thickness, 0.3mm to 1mm color plate, 304 stainless steel. The flame retardant grade is B2. PU panel are injected with 100% polyurethane (CFC free) with an average foam-in-place density of 42-44kg/m³.With our cold room panels, you can efficiently insulate your cold room and freezer room.Taking polyurethane with excellent insulation performance as core material and pre-painted galvanized iron (PPGI/color steel), 304 stainless steel or aluminum as external material, PU sandwich panel can reduce the heat conduction due to difference between internal and external temperature to achieve maximum efficiency of freezing and refrigeration system.

Cold Room 100mm Pu Sandwich Panel

CAS GYW cold room pu sandwich panel, 50mm, 75mm, 100mm, 120mm, 150mm,180mm and 200mm thickness, 0.3mm to 1mm color plate, 304 stainless steel. The flame retardant grade is B2. PU panel are injected with 100% polyurethane (CFC free) with an average foam-in-place density of 42-44kg/m³.With our cold room panels, you can efficiently insulate your cold room and freezer room.