- Home

- Freezer Room

- Meat seafood ice cream storage room

Meat seafood ice cream storage room

Meat seafood ice cream storage Suitable for storage: chicken,dumplings, meat, ice cream, fish, seafood and so on.

1. -30~-40 degrees, adjust according to the items you need to store.

2. High-density foam storage board, good heat preservation effect

- General Details

- Contact Us

- Related Products

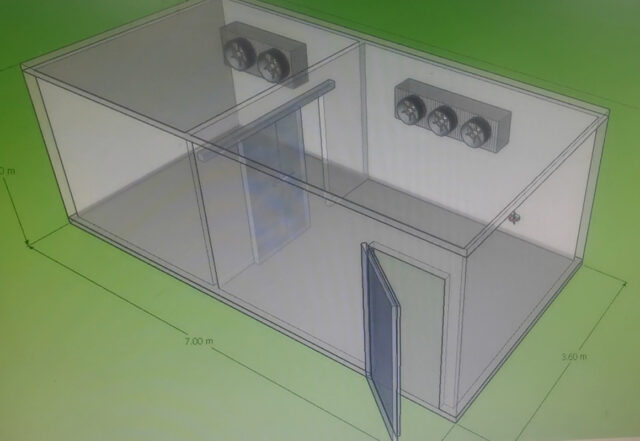

Meat seafood ice cream storage room Parameter

| Dimension | Customized length, width, height | ||

| Refrigeration unit | Carrier/Bitzer/Copeland etc. | ||

| Refrigeration type | Air cooled/water cooled/evaporation cooled | ||

| Refrigeration | R22,R404a,R447a,R448a,R449a,R507a Refrigerant | ||

| Defrost Type | Electric defrosting | ||

| Voltage | 220V/50Hz,220V/60Hz,380V/50Hz,380V/60Hz,440V/60Hz optional | ||

| Panel | New material polyurethane insulation panel,43kg/m3 | ||

| Panel thickness | 180mm 200mm | ||

| Type of door | Hanged door,sliding door,double swing electric sliding door,truck door | ||

| Temp. of room | -30~-40℃ optional | ||

| Functions | chicken,dumplings, meat, ice cream, fish, seafood ,etc. | ||

| Fittings | All necessary fittings are included,optional | ||

| Place to assemble | Indoor/out door(concrete construction building/steel construction building) | ||

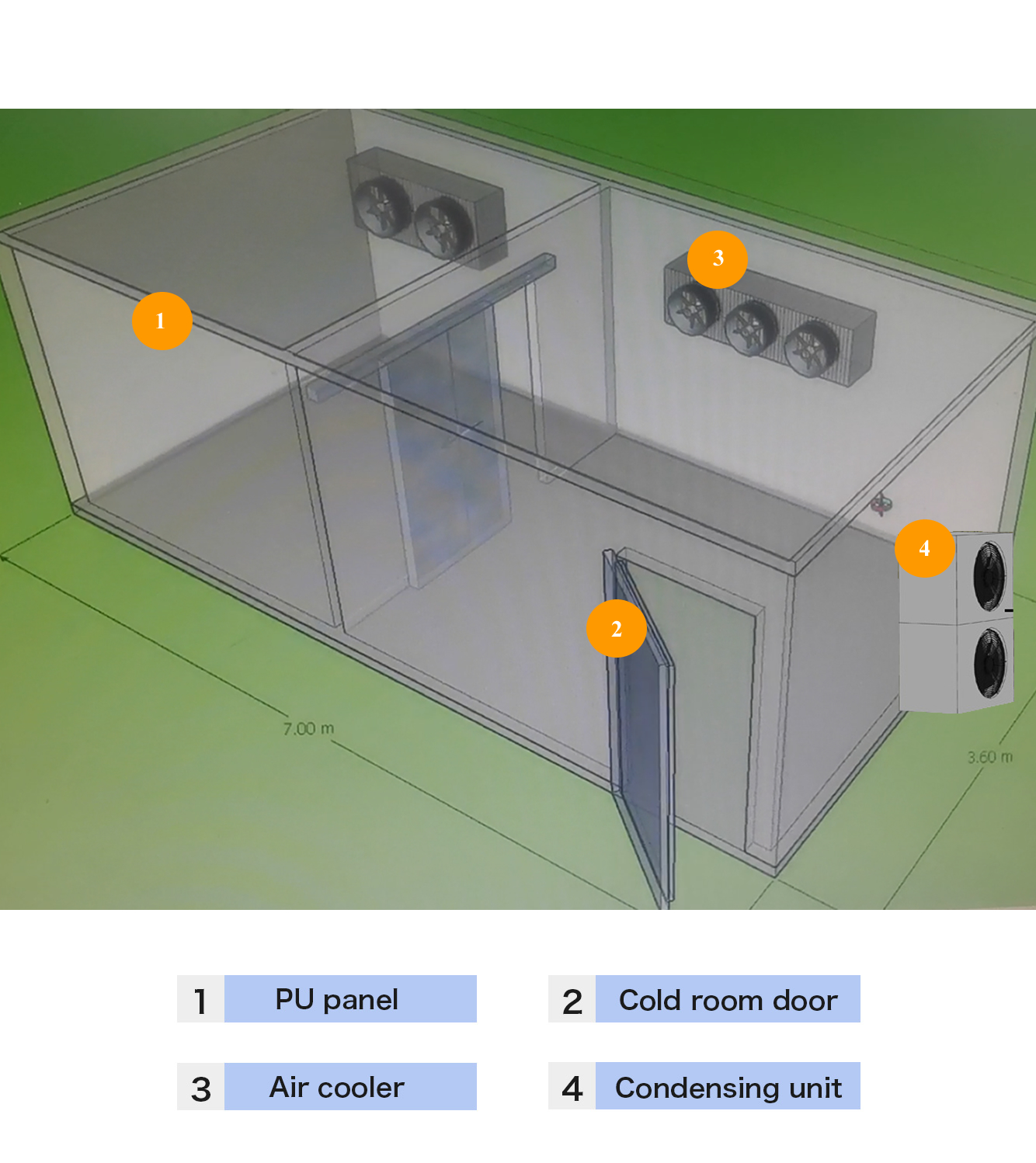

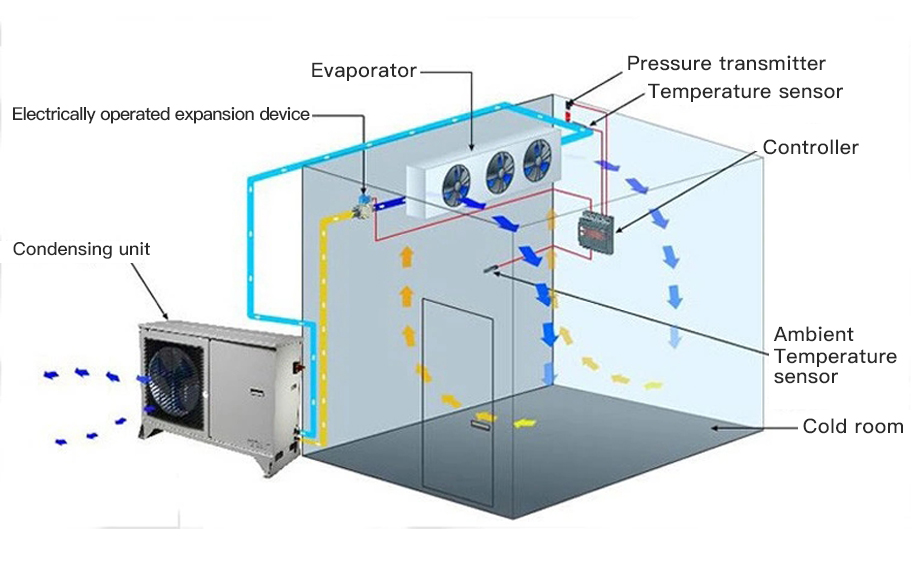

Cold room structure:

Cold room applications:

In food industry, cold room is usually used in food process factory, slaughterhouse, fruit and vegetable

warehouse,supermarket,hotel, restaurant, etc.

In medical industry, cold room is usually used in hospital, pharmaceutical factory, blood center, gene center, etc.

Other related industries, such as chemical factory, laboratory, logistics center, they also need cold room.

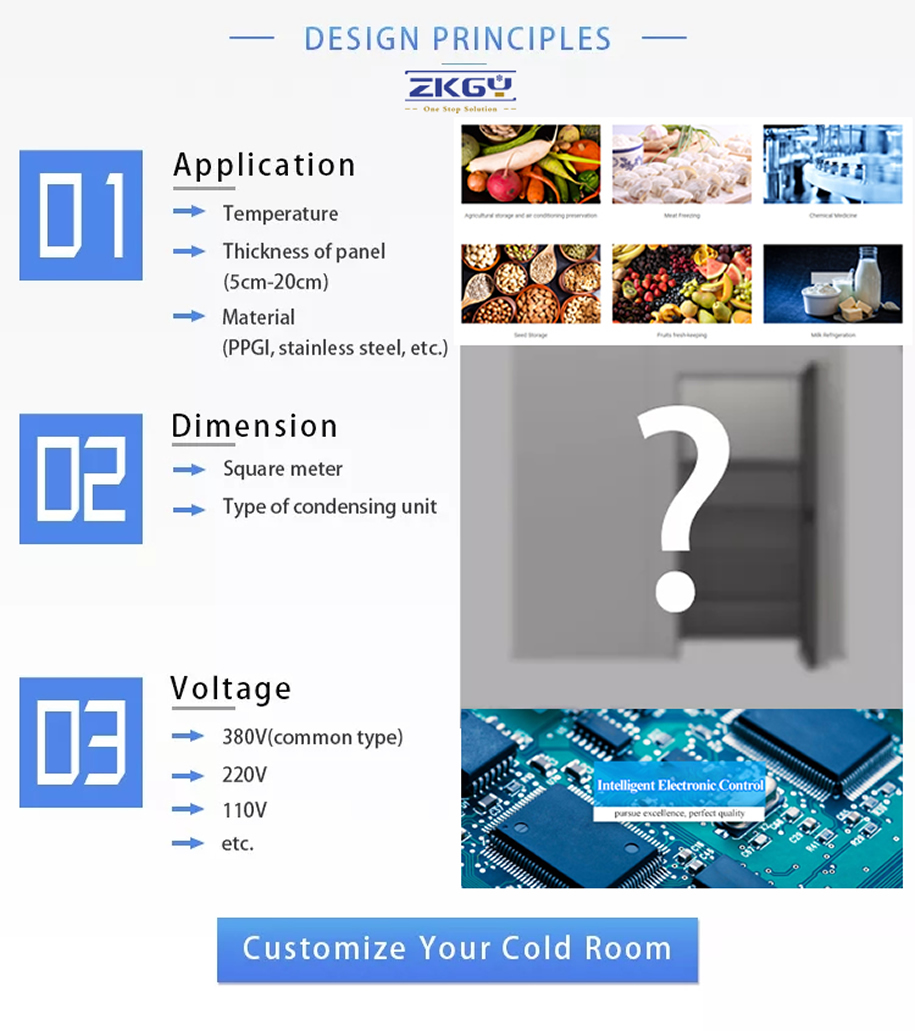

Design principle

For cold room projects, the following factors should be fully considered:

|

Application for example

|

Room Temperature

|

||

|

Fruit & Vegetable

|

-5 to 10 ℃

|

||

|

Chemical factory,medicine

|

0 to 5 ℃

|

||

|

Ice cream, ice storage room

|

-10 to -5 ℃

|

||

|

Frozen meat storage

|

-25 to -18 ℃

|

||

|

Fresh meat storage

|

-40 to -30 ℃

|

|

General details of fresh cold room

|

||||

|

Reference dimension(L*W*H)

|

6m*4m*2.5m

|

8m*5m*2.5m

|

10m*6m*2.5m

|

11m*6m*3m

|

|

Application

|

Usually for storage of fresh vegetables and fruits

|

|||

|

Temperature

|

-5°C ~ +5°C

|

|||

|

Power

|

380V/50HZ/3Phase(can be customized)

|

|||

|

Cold room structure

|

||||

|

Surface metal (Take PPGI on both sides for example)

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

|

Thickness of PU panel

|

100mm

|

100mm

|

100mm

|

100mm

|

|

Cold room door(W*H)

|

Hinged door 0.8m*1.8m

|

Hinged door 0.8m*1.8m

|

Manual sliding door 1.5m*2m

|

Manual sliding door 1.8m*2m

|

|

Refrigeration Equipment

|

||||

|

Compressor brand

|

Bitzer

|

Bitzer

|

Bitzer

|

Bitzer

|

|

Compressor type

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

|

Compressor model

|

4FES-5Y

|

4DES-7Y

|

4VES-10Y

|

4PES-15Y

|

|

Refrigerant

|

R404a

|

R404a

|

R404a

|

R404a

|

|

Condenser model

|

FNH-12.5/41

|

FNH-17/60

|

FNH-23/80

|

FNH-35/120

|

|

Evaporator model

|

DD-30

|

DD-60

|

DD-80

|

DD-120

|

|

General details of freezer cold room

|

||||

|

Reference dimension(L*W*H)

|

4m*4m*2.5m

|

6m*4m*2.5m

|

6m*6m*2.5m

|

6m*8m*2.5m

|

|

Application

|

Usually for storage of frozen fish, meat and seafood

|

|||

|

Temperature

|

-20°C ~ -18°C

|

|||

|

Power

|

380V/50HZ/3Phase(can be customized)

|

|||

|

Cold room structure

|

||||

|

Surface metal (Take PPGI on both sides for example)

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

|

Thickness of PU panel

|

150mm

|

150mm

|

150mm

|

150mm

|

|

Cold room door(W*H)

|

Hinged door 0.8m*1.8m

|

Hinged door 0.8m*1.8m

|

Manual sliding door 1.5m*2m

|

Manual sliding door 1.5m*2m

|

|

Refrigeration Equipment

|

||||

|

Compressor brand

|

Bitzer

|

Bitzer

|

Bitzer

|

Bitzer

|

|

Compressor type

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

|

Compressor model

|

4DES-5Y

|

4TES-9Y

|

4PES-12Y

|

4HE-18Y

|

|

Refrigerant

|

R404a

|

R404a

|

R404a

|

R404a

|

|

Condenser model

|

FNH-12.5/41

|

FNH-17/60

|

FNH-23/80

|

FNH-35/140

|

|

Evaporator model

|

DD-30

|

DD-60

|

DD-100

|

DD-140

|

|

Parameter

|

|||

|

Brand

|

CASGYW or OEM / ODM

|

||

|

Size

|

Customized

|

||

|

Temperature

|

-50°C to 50 °C

|

||

|

Voltage

|

380V, 220V or Customized

|

||

|

Main parts

|

Polyurethane(PU) sandwich panel

|

||

|

Cold room door

|

|||

|

Condensing unit——German Bitzer, American Emerson, GREE, etc.

|

|||

|

Air cooler——ZKGY,EDEN, etc.

|

|||

|

Fittings

|

Valves, copper pipe, thermal insulation pipe, wire, PVC pipe for wire, PVC door curtain for sliding door, LED light, switch,electrode, insulating tape, belting, etc.

|

||

|

Certification

|

ISO9001:2015, BV, SGS, TÜV

|

||

|

Cold room panelWe use fluoride-free material, it is more environment-friendly. Our cold room panels can reach fireproof level B2.

Polyurethane panel is foamed by high pressure with density of 38-42 kg/m3. So the thermal insulation will be good.

|

|

Cold room door

We have different types of cold room door, such as hinged door, sliding door, free door and other types of doors according to your requirement. |

|

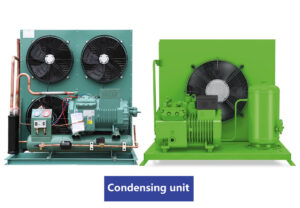

Condensing unitWe use the world famous compressor like German Bitzer, American

Emerson, etc.

It is easy to operate the automatic high-precision digital controller with high efficiency.

|

|

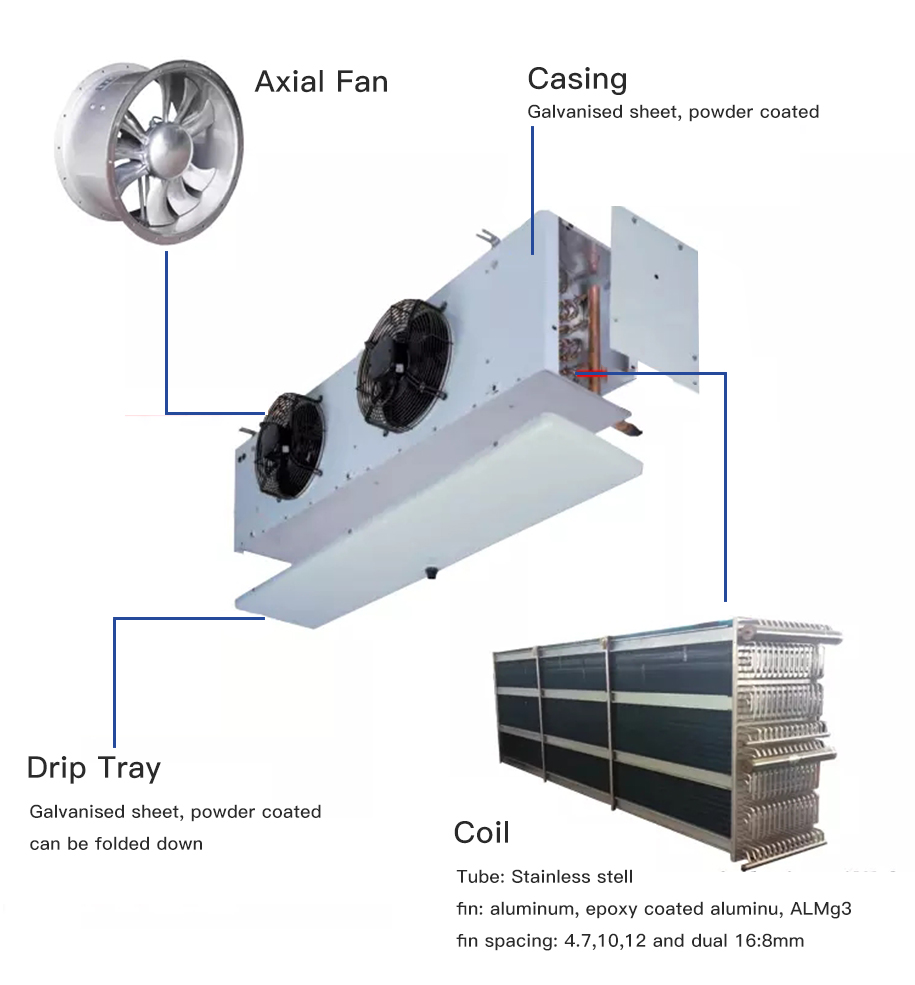

Evaporator(Air cooler)————————————————————————————————————————————————— Model: DD series, DJ series, DL series.

DD series is suitable for medium temperature;

DJ series is suitable for low temperature;

DL series is suitable for high temperature.

|

|

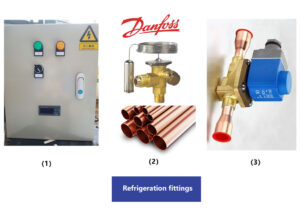

Refrigeration fittings————————————————————————————————————————————————— (1)Temperature controller

Famous brand: Italy Dixell with DELIXI or Korean LG, French Schneider

(2)Valve Parts

Famous brand: Denmark Danfoss

(3)Copper pipe and connection

(4)Thermal insulation pipe, wire, PVC pipe, PVC door curtain for sliding door,

LED light, switch, electrode, insulating tape, belting, etc.

|

How to Installation:

Step 2: Wall panel

Step 3: Ceiling panel

Panels will be marked according to drawing and connected by cam locks, you just need to lock different panels together, then seal them with sealant to keep sealed.

You can watch this following video about how to install cold room.

50mm/75mm/100mm/150mm EPS Sandwich Panel

50mm/75mm/100mm/150mm EPS Sandwich Panel :EPS sanwich panel is widely used for wall and roof of mobile office/building, gymnasium,villa, guard booth, floor heating , steel structure building and packaging industry,Purification workshop ceiling, warehouses.EPS sandwich panel is a proven construction material well-suited to the extremes. It is a cost-effective, lightweight construction material with excellent insulation properties. ♦ The advantages of EPS Panel include: ♦ High load bearing capacity at low weight ♦ Effective and durable thermal insulation ♦ Absolute water and vapour barrier ♦ Air-tightness for controlled environments ♦ Long life, low maintenance ♦ Lightweight, fast and economic construction ♦ Hygienic food grade finish ♦ Most cost effective insulation material available

Cold Room 150mm Pu Sandwich Panel

Pu sandwich panel structure:Cam-lock type PU sandwich panel is connected by cam-lock, it is easy to install, and has advantages of fire resistance, high compressive strength, good sealing, and etc. It is suit for temperature of -50°C to +100°C, and nonperishable. Taking polyurethane with excellent insulation performance as core material and pre-painted galvanized iron (PPGI/color steel), 304 stainless steel or aluminum as external material, PU sandwich panel can reduce the heat conduction due to difference between internal and external temperature to achieve maximum efficiency of freezing and refrigeration system.

120mm Cold Room Pu Sandwich Panel

CAS GYW cold room pu sandwich panel, 50mm, 75mm, 100mm, 120mm, 150mm,180mm and 200mm thickness, 0.3mm to 1mm color plate, 304 stainless steel. The flame retardant grade is B2. PU panel are injected with 100% polyurethane (CFC free) with an average foam-in-place density of 42-44kg/m³.With our cold room panels, you can efficiently insulate your cold room and freezer room.

Cold Room Hinged Door

Cold Room Hinged Door designed and manufactured by GYW is widely used for cold rooms or freezer rooms from temperatures of -36° C to normal operating temperatures. Cold room hinged door panels are seamlessly joined together by means of tongue and groove, they are locked together by cam-lock on each side of the panel to ensure air tight joints. Cam-lock design fastener to install with the cold room tightly and strongly. The cold room door panel with thickness of 100mm or 150mm is commonly applied. All our cold room doors are made with the CFC-free insulated PU panel covered with stainless steel or galvanized steel that meet EC/USDA international hygiene standards.